Fertigungstechnik Müller GmbH with

universal premium 25/35

Fertigungstechnik Müller GmbH with

universal premium 25/35 "Our demands on the loading robot have been met without exception."

Jörg Müller, Director, Fertigungstechnik Müller GmbH

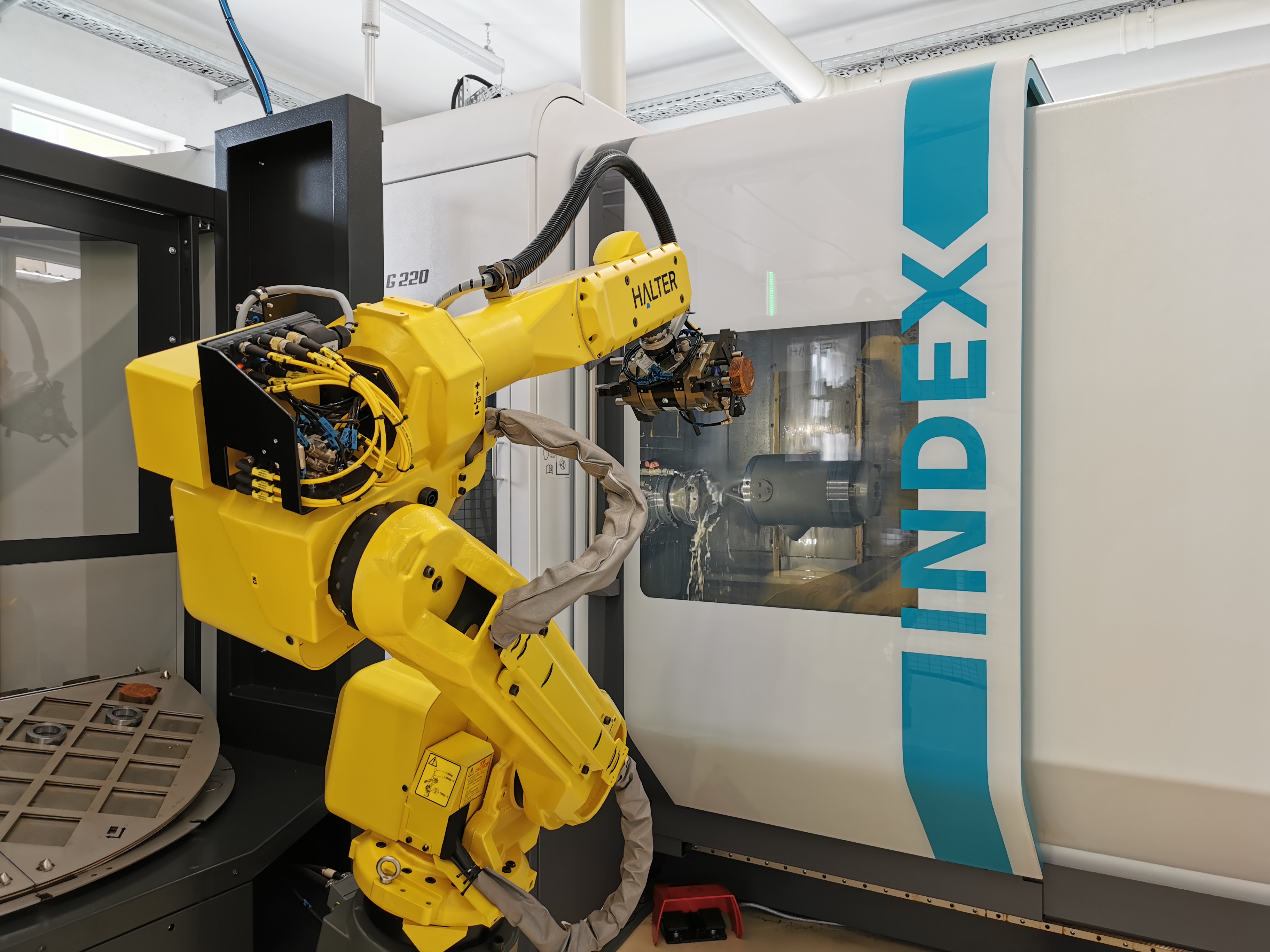

The decision to incorporate robot automation was made after managing director Jörg Müller saw the combination of a HALTER LoadAssistant and an Index G220 at a customer's site and recognized the benefits for his production. The purchase was motivated not only by the lack of skilled workers of the Thuringian manufacturer of prismatic and rotationally symmetric products; the wage-price spiral and the associated cost pressure was also a decisive factor.

"Our employees were eagerly awaiting the loading robot. But the user-friendliness and personal support from the HALTER team made it very easy for us to get started," says Christian Gütter, Head of Production.

Since commissioning in spring 2019, the production output of the manufacturing cell has increased significantly and new products are constantly being loaded with the robot. In this way, the high-quality turning/milling centre with the process automation can be used to maximum capacity and the acquisition costs can be recovered quickly. Fertigungstechnik Müller GmbH is certified to DIN-ISO 9001:2008 and has installed a quality management system. Through consistent and uncompromising investment in modern CNC technology for the entire production and measuring area, the family business enjoys the highest reputation among its customers.

Production of prismatic and rotationally symmetrical products

25 employees

Königsee-Rottenbach

Germany

HALTER CNC Automation B.V.

Sluiswachter 20b

3861 SN Nijkerk

The Netherlands

T: +31 88 015 74 00

info@haltercnc.com

VAT ID: NL869021229B01

Company ID: 99512114

HALTER CNC Robotics LLC

21995 Fillmore Road

Cascade, Iowa 52033

United States

T: 800-314-8261

info@halterusa.com

VAT ID: US473961908