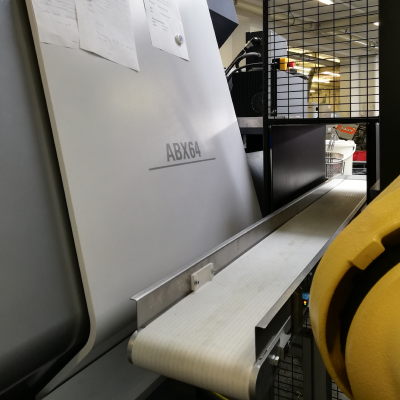

Unloading workpiece onto a conveyor belt

A workpiece can be unloaded onto an external location.

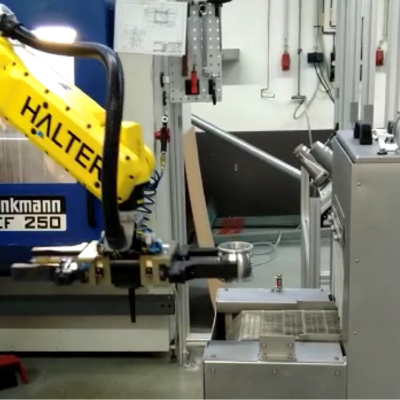

These loading robots offer the widest flexibility in part size and shape. They handle round and rectangular parts, irregular forms, and shafts with ease, making them ideal when your workpieces differ from job to job. A solid all-round option that works on both turning and milling machines.

Basic Pro is a basic, yet professional loading robot for turning and milling. Industrial technology for the price of a cobot system.

The Universal Compact 12 is a robotic loading solution for turning and milling with the smallest footprint in our Universal product range, at the most competitive price in the market. covering the complete range of workpieces up to 135 mm.

The Universal Premium 25/35 is a robotic loading solution for turning and milling, covering the complete range of workpieces up to 270 mm.

The Universal Big 35/70 is a robotic loading solution for turning and milling and is designed especially for loading heavy workpieces. It also has a high capacity for shaft handling up to 600 mm.

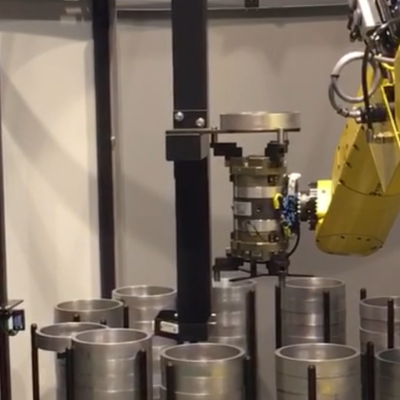

Our TurnStackers are made for round, symmetrical parts that fit efficiently in stacks— bushings, rings and flanges for example. Stacking gives you high capacity in a compact footprint, making them very productive for repetitive turning work.

The TurnStacker Compact 12 is a robotic loading solution for turning with the smallest footprint in our TurnStacker product range. Great for loading flanges and gears. It has a high capacity for diameters up to 160 mm.

The TurnStacker Premium 25/35 is a robotic loading solution for turning. Great for loading flanges and gears. It has a high capacity for diameters up to 230 mm.

The TurnStacker Big 35/70 is a robotic loading solution for turning and is designed especially for loading heavy workpieces. It also has a high capacity for diameters up to 300 mm.

Our MillStackers are designed for uniform rectangular parts that can be placed in stacks. This ensures solid capacity and stable handling, making them a strong fit for steady milling work and series production.

The MillStacker Compact 12 is a robotic loading solution for milling with the smallest footprint in our MillStacker product range. It has a high capacity for workpieces up to 200 mm.

The MillStacker Premium 25/35 is a robotic loading solution for milling with a high capacity for workpieces up to 280 mm.

A workpiece can be unloaded onto an external location.

The finished workpieces can be unloaded onto an additional pallet. This is ideal if you want to add buffer capacity or load heavy workpieces.

After one side of the workpiece is machined (OP10), the half-finished workpiece is positioned on a turnover station. Then it can be gripped on the other side of the workpiece and again placed in the chuck or vice of the CNC machine so the second side can be machined (OP20).

The workpiece can be collected from a pickoff tool after machining in the CNC machine.

The robot unloads the CNC machine and then moves the workpiece to an external cleaning station before returning the workpiece to the HALTER LoadAssistant.

The robot unloads the CNC machine and moves the workpiece to an external measuring station before returning the workpiece to the HALTER LoadAssistant. The robot can place rejected workpieces in a separate position.

The workpiece is axially taken from the loading table and positioned on a side-gripping station. Then it is regripped perpendicularly and positioned in the vice of the CNC machine. This allows a high buffer capacity for long workpieces.

Long shafts can be loaded and unloaded with seamless placement in the chuck, creating high capacity for shafts up to 600 mm, with standard grid plates and up to 1000 mm with custom grid plates.

Halter’s application engineering team can design grid plates and special gripper fingers for your specific workpieces or castings - for example, if you want to automate castings or other workpieces that require special handling. All these customer-specific solutions can be implemented in the user-friendly HALTER SmartControl. The flexibility of our solutions ensures that you can automate an even greater variety of workpieces.

HALTER CNC Automation B.V.

Sluiswachter 20b

3861 SN Nijkerk

The Netherlands

T: +31 88 015 74 00

info@haltercnc.com

VAT ID: NL869021229B01

Company ID: 99512114

HALTER CNC Robotics LLC

21995 Fillmore Road

Cascade, Iowa 52033

United States

T: 800-314-8261

info@halterusa.com

VAT ID: US473961908