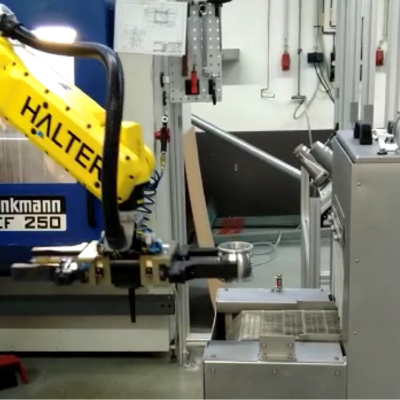

Loading robot for turning and milling machines

%20Product%20pictures/Universal-Big-35-70%20(resized).png)

%20Product%20pictures/Universal-Big-35-70%20(resized).png)

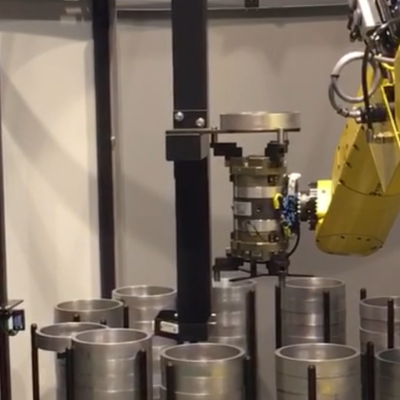

The Universal Big 35/70 is a loading robot for turning and milling and is specially designed for loading heavy workpieces and a large buffer capacity.

For turning and milling

Maximum diameter 300 mm - maximum dimension LxW 300 mm x 300 mm

Shaft loading up to a length of 600 mm standard and up to 1000 mm optional

Set-up time of less than 5 minutes

Preparing new batch while the robot is running

Machine access is maintained

With a 35 or 70 kg robotarm

Many extra functionalities - see here

%20Product%20pictures/Universal-Big-35-70%20(resized).png)

No robot experience required

Programme configured in just a few steps

Setup time of less than 5 minutes

Ingenious in its simplicity

Discuss which machine you would like to automate

Explanation of the principle of Halter solutions and our portfolio

Demonstration how easy it is to operate a plug-and-play robot

Personalised advice on which solution is right for you

Explanation of the implementation process: interface, installation and training

After one side of the workpiece is machined (OP10), the half-finished workpiece is positioned on a turnover station. Then it can be gripped on the other side of the workpiece and again placed in the chuck or vice of the CNC machine so the second side can be machined (OP20).

The finished workpieces can be unloaded onto an additional pallet. This is ideal if you want to add buffer capacity or load heavy workpieces.

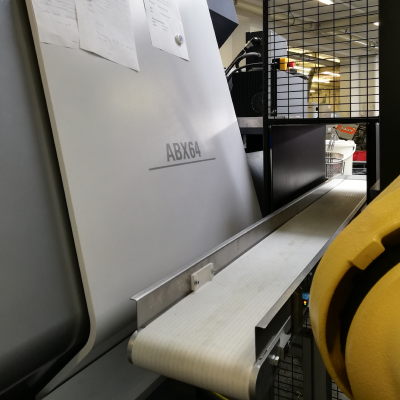

A workpiece can be unloaded onto an external location, i.e. a conveyor belt.

The workpiece can be collected from a pickoff tool after machining in the CNC machine.

The robot unloads the CNC machine and then moves the workpiece to an external cleaning station before returning the workpiece to the HALTER LoadAssistant.

The robot unloads the CNC machine and moves the workpiece to an external measuring station before returning the workpiece to the HALTER LoadAssistant. The robot can place rejected workpieces in a separate position.

The workpiece is axially taken from the loading table and positioned on a side-gripping station. Then it is regripped perpendicularly and positioned in the vice of the CNC machine. This allows a high buffer capacity for long workpieces.

Long shafts can be loaded and unloaded with seamless placement in the chuck, creating high capacity for shafts up to 600 mm, with standard grid plates and up to 1000 mm with custom grid plates.

Halter’s application engineering team can design grid plates and special gripper fingers for your specific workpieces or castings - for example, if you want to automate castings or other workpieces that require special handling. All these customer-specific solutions can be implemented in the user-friendly HALTER SmartControl. The flexibility of our solutions ensures that you can automate an even greater variety of workpieces.

Halter's application engineering team can design grid plates and special gripper fingers for your specific workpieces. For example, if you have castings or workpieces that you need to be automated in a specific way. All these customer-specific solutions can be implemented in the user-friendly HALTER SmartControl. The flexibility of the solutions we offer allows you to automate even more different workpieces.

Basic Pro is a basic, yet professional loading robot for turning and milling. Industrial technology for the price of a cobot system.

The Universal Compact 12 is a robotic loading solution for turning and milling with the smallest footprint in our Universal product range, at the most competitive price in the market. covering the complete range of workpieces up to 135 mm.

The Universal Premium 25/35 is a robotic loading solution for turning and milling, covering the complete range of workpieces up to 270 mm.

HALTER CNC Automation GmbH

Gewerbering 7

47661 Issum

Germany

T: +49 2835 955 3990

info@haltercnc.com

VAT ID: DE326335222

Company ID: HRB 16121

HALTER CNC Robotics LLC

21995 Fillmore Road

Cascade, Iowa 52033

United States

T: 800-314-8261

info@halterusa.com

VAT ID: US473961908