WORKPIECE TURNOVER FUNCTION FOR TWO-SIDED MACHINING

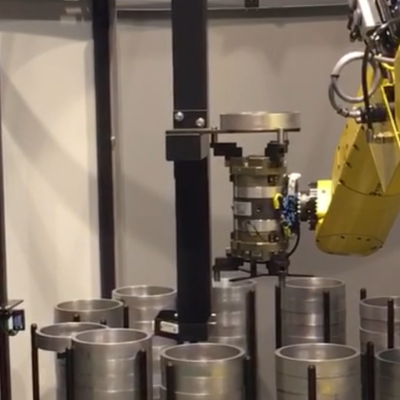

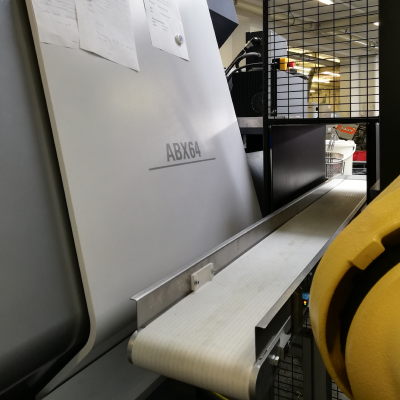

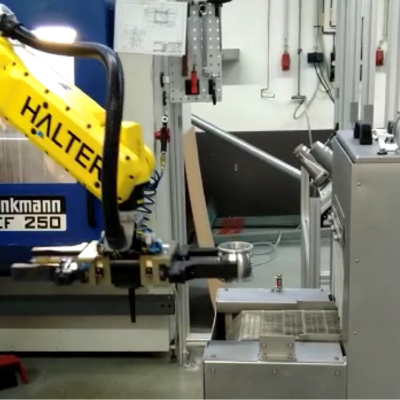

After one side of the workpiece is machined (OP10), the half-finished workpiece is positioned on a turnover station. Then it can be gripped on the other side of the workpiece and again placed in the chuck or vice of the CNC machine so the second side can be machined (OP20).

%20Product%20pictures/Universal-Big-35-70%20(resized).png)

%20Product%20pictures/TurnStacker-Compact%20(resized).png)

%20Product%20pictures/TurnStacker-Big-35-70%20(resized).png)

%20Product%20pictures/MillStacker-Compact-12%20(resized).png)

%20Product%20pictures/MillStacker-Big-35-70%20(resized).png)