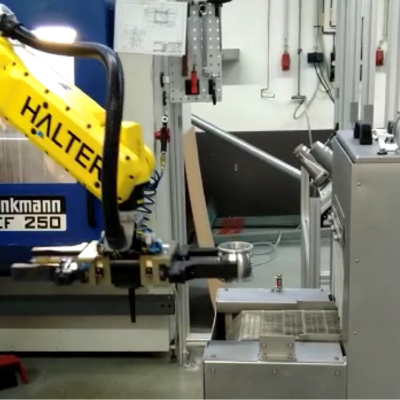

Our compact loading robot for turning and milling machines

%20Product%20pictures/Universal-Compact-12-web.png)

%20Product%20pictures/Universal-Compact-12-web.png)

Backside set up or reloading keeps the robot running — refill anytime when it fits your schedule. No idle machine time while waiting for your reload.

After one side of the workpiece is machined (OP10), the half-finished workpiece is positioned on a turnover station. Then it can be gripped on the other side of the workpiece and again placed in the chuck or vice of the CNC machine so the second side can be machined (OP20).

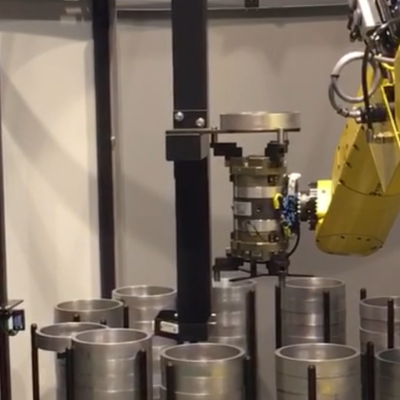

The finished workpieces can be unloaded onto an additional pallet. This is ideal if you want to add buffer capacity or load heavy workpieces.

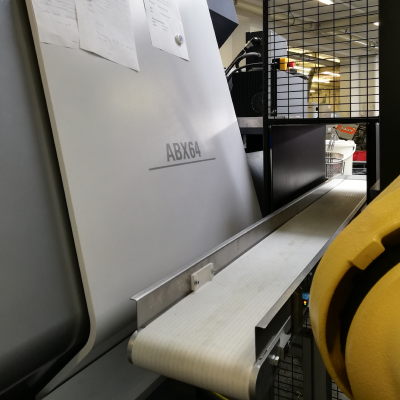

A workpiece can be unloaded onto an external location, i.e. a conveyor belt.

The workpiece can be collected from a pickoff tool after machining in the CNC machine.

The robot unloads the CNC machine and then moves the workpiece to an external cleaning station before returning the workpiece to the HALTER LoadAssistant.

The robot unloads the CNC machine and moves the workpiece to an external measuring station before returning the workpiece to the HALTER LoadAssistant. The robot can place rejected workpieces in a separate position.

The workpiece is axially taken from the loading table and positioned on a side-gripping station. Then it is regripped perpendicularly and positioned in the vice of the CNC machine. This allows a high buffer capacity for long workpieces.

Long shafts can be loaded and unloaded with seamless placement in the chuck, creating high capacity for shafts up to 600 mm, with standard grid plates and up to 1000 mm with custom grid plates.

Halter’s application engineering team can design grid plates and special gripper fingers for your specific workpieces or castings - for example, if you want to automate castings or other workpieces that require special handling. All these customer-specific solutions can be implemented in the user-friendly HALTER SmartControl. The flexibility of our solutions ensures that you can automate an even greater variety of workpieces.

Every hour your CNC stands still is money gone. Automation keeps your spindle cutting — even when people aren’t available.

Good operators are hard to find and harder to keep. A robot takes over the repetitive work so your skilled people stay — and new talent actually wants the job.

Shops that automate quote faster, deliver faster, and win more orders. Don’t let the next job go to someone else.

HALTER CNC Automation B.V.

Sluiswachter 20b

3861 SN Nijkerk

The Netherlands

T: +31 88 015 74 00

info@haltercnc.com

VAT ID: NL869021229B01

Company ID: 99512114

HALTER CNC Robotics LLC

21995 Fillmore Road

Cascade, Iowa 52033

United States

T: 800-314-8261

info@halterusa.com

VAT ID: US473961908